Ingredients

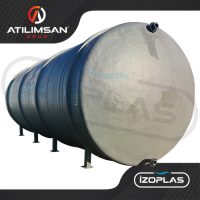

Chemical tanks are produced for stocking of chemical liquid and acid. Sometimes, chemical liquid could be dangerous and it should be stored with safety. So that we have three alternative solutions for chemical storage tanks.

Chemical Tanks

Usage Areas

Chemical tanks use at textile factories, chemical raw material manafacturer factories and all places that requires chemical storage.

Types of Chemical Tanks

We can produce chemical tanks in 3 types. Fiberglass (called as vinyl ester) tanks, polythene tanks and pvc tanks coated with frp.

Vinyl Ester Tanks

Chemical tanks usually use for storage of different acid types. The most production is made for hydrochloric acid, sodium hydroxide, sodium hypochloride, ferric chloride acid types.

Also tanks could be used for storage of chemical waste.

Production Process

The first production group is the vinlyster for chemical tanks. Vinyl ester is a epoxy resin type that is resisted for acid and other chemical liquids. The concentration rate and stock tempature is so important for vinylester tanks. You can view resistance table for your acid type at above.Advantages of Vinylester Tanks

- Tank sizes are changable.

- Production can be supplied as cylindrical, cubic, silo or a chemical pool.

- Inlet and outlet connections are resisted to acid and chemical. Connections are supplied accordingly your request. Inside threaded, flange or pipe, how you want.

- Production could be made as horizontal or vertical in all volumes.

- Tanks are resist to weather conditions.

- Tanks don’t react to your chemicals.

- Vinyl ester tanks are stainless.

- Vinyl ester tanks’ usefull life is so long compare with than other tanks.

- Any equipments can be fixed to vinylester tanks. Ladder, free-flange inlets and outlets or other equipments that you want.

Polythene Chemical Tanks

Polythene is a thermoplastic that has high chemical resistance. Production process is same with water tanks. Chemical tanks are thicker than water tanks. We designate polythene chemical tanks’ thickness according to chemical liquid that you will store in it.

Advantages & Disadvantages

- This tank group is less costly than others.

- Production is mass.

- Chemical resistance is high to chemical liquids in all concentration rates.

- Tanks are not affected by weather conditions.

- There will be not any reaction with chemicals.

- The main disadvantage of polythene chemical tanks is no chance to change tanks’ dimensions.

- Also location and dimension of inlet can not be changed.

- Polythene tanks can not be repaired.

- Produciton is limited to 5000 Liter for horizontal tanks.

PVC & FRP Tanks

These production group is usefull for storage of dangerous acid types like sulphuric acid concentration rate is above 75%. PVC tank is produced with requested dimensions and coated with vinyl ester resin and fiberglass. Thickness is designated accordingly tank volume.

These tank group is more costly than the others. Its resistance is so high to all chemicals but tempature shall be ambient. We can design its inlet and outlets how you want. Also dimensions are changable.

PVC Acid tanks are produced in 4 steps. You can see production process at below. Also pictures at above show production process step by step.

Producing of pvc tank. PVC Sheets are shaped accordingly requested sizes. And PVC body of tank is produced.

PVC tanks are sanded to coat fiberglass and epoxy resin. For better coating process tank shall be sanded.

On this step, we coat pvc tank’s sanded skin with fiberglass and vinyl ester resin. PVC is fragile structure, so we reinforce it with fiberglass.

Last step of production. We clean coated skin of tank and paint it. Tanks are tested with water and delivered to you. For shipping defection, retest your tank before filling acid.

Terms of Use

- Which chemical liquid that you will stock in tanks, you should tell about it. Concentration rate and its stock tempature is important for tank useful life.

- Please fix your tank on concrete ground.

- Don’t exceed the concentration rate and tempature that you tell.

- Please contact with us for any request.

All Rights Reserved | ATILIMSAN GRUP A.S.